Understanding Modern Office Accessories: The Evolution of Acrylic PP Clips

The landscape of office supplies has dramatically evolved over the past decade, with acrylic PP clips emerging as an essential component in contemporary workspaces. These versatile accessories combine functionality with aesthetic appeal, representing a perfect blend of modern design sensibilities and practical utility. As offices transition towards more sophisticated and design-conscious environments, the demand for well-crafted acrylic PP clips continues to grow exponentially.

Modern stationery brands recognize that even the smallest office accessories can make a significant impact on workspace organization and visual appeal. The clear, pristine appearance of acrylic material paired with the durability of polypropylene creates clips that are both visually appealing and highly functional. This combination has revolutionized how we think about document organization and desk accessories.

Essential Design Principles for Premium Clip Manufacturing

Material Selection and Quality Standards

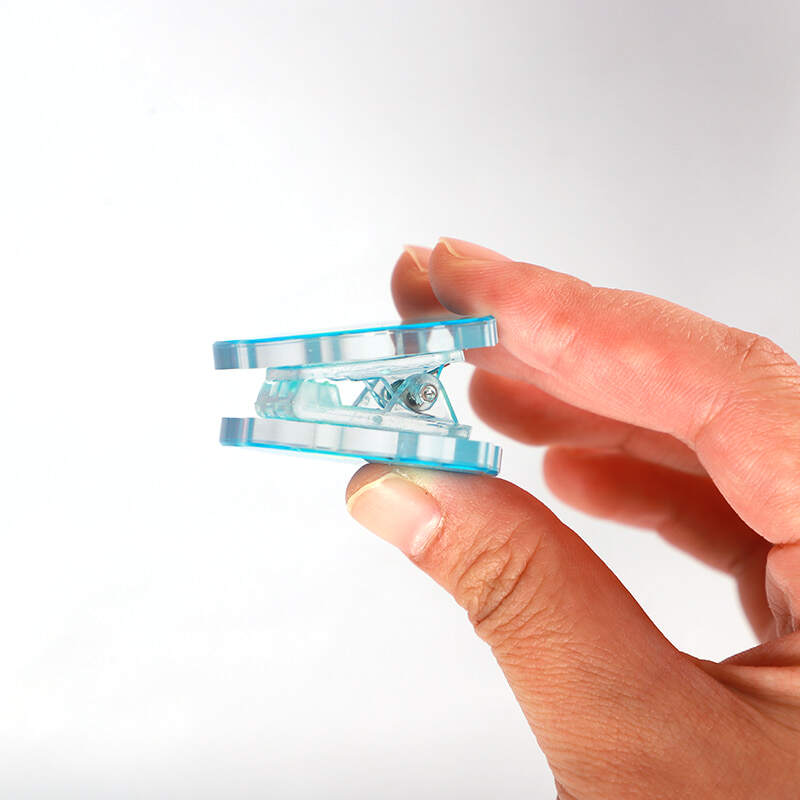

The foundation of exceptional acrylic PP clips lies in the careful selection of materials. Premium-grade acrylic should be crystal clear, resistant to yellowing, and maintain its transparency over time. The polypropylene components must offer the perfect balance of flexibility and durability, ensuring the clips maintain their grip strength without becoming brittle or losing shape.

Manufacturing standards should prioritize using food-grade materials, ensuring the clips are safe for everyday office use. The thickness of the acrylic should be carefully calibrated – typically between 2mm and 4mm – to provide adequate strength while maintaining a sleek profile. The PP components require precise engineering to create smooth, consistent spring action that won't deteriorate with repeated use.

Ergonomic Considerations in Clip Design

The user experience should be at the forefront of clip design. The opening mechanism needs to be smooth and require minimal force, while still providing secure document retention. The clip's edges must be perfectly rounded to prevent any sharp corners that could cause discomfort or paper damage. Consider incorporating subtle texture patterns on grip surfaces to enhance usability without compromising the clean aesthetic.

Size variations should be developed to accommodate different document thicknesses and use cases. Standard sizes might range from 15mm to 75mm in width, with corresponding grip strengths tailored to specific applications. The spring mechanism should maintain consistent pressure across the entire gripping surface to prevent document damage or slippage.

Innovative Design Features for Market Differentiation

Aesthetic Enhancement Techniques

Modern acrylic PP clips can incorporate various design elements to stand out in the market. Consider implementing subtle color tints in the acrylic components while maintaining transparency. Custom edge finishing techniques, such as frosted or beveled edges, can add sophisticated detail without compromising functionality. Surface treatments might include minimal etched patterns or brand logos that become visible when the clip catches light.

Advanced manufacturing processes allow for the integration of metallic accents or custom-colored PP components that complement the acrylic elements. These design features should enhance the product's visual appeal while maintaining its professional appearance and functionality.

Sustainable Design Implementation

Environmental consciousness is increasingly important in office supply design. Incorporate recycled PP materials where possible, and ensure all components are easily separable for end-of-life recycling. Consider developing clips with replaceable PP mechanisms to extend product lifespan and reduce waste. The packaging should also reflect this commitment to sustainability, utilizing minimal, recyclable materials.

Design for durability is another crucial aspect of sustainable manufacturing. The clips should be engineered to withstand years of daily use, reducing the need for frequent replacement. This includes UV-resistant acrylic formulations and stress-tested PP components that maintain their properties over time.

Manufacturing Process Optimization

Quality Control Measures

Implementing robust quality control procedures is essential for consistent product excellence. Each batch of acrylic PP clips should undergo rigorous testing for grip strength, spring mechanism durability, and overall build quality. Automated inspection systems can verify dimensional accuracy and surface finish consistency. Regular material testing ensures that both acrylic and PP components meet specified quality standards.

Establish clear quality benchmarks for various aspects including transparency levels, clip tension, and surface finish. Implement statistical process control methods to monitor production variables and maintain consistent quality across manufacturing runs. Regular calibration of tools and equipment ensures precise tolerances are maintained.

Production Efficiency Strategies

Optimize the manufacturing process through careful planning and modern production techniques. Utilize advanced injection molding systems for PP components to ensure consistent quality and reduce waste. Implement automated assembly processes where possible while maintaining necessary quality control checkpoints. Consider modular tool designs that allow quick changeovers for different clip sizes and styles.

Establish efficient material handling systems to minimize production time and reduce the risk of surface damage during manufacturing. Develop standardized procedures for each production step, from material preparation to final packaging, ensuring consistent quality and efficient resource utilization.

Market-Specific Design Adaptations

Corporate Client Customization

Design flexibility is crucial for meeting corporate client needs. Develop a range of customization options that allow for brand color integration and logo placement without compromising the clip's functionality. Create specialized sizing options for specific document management requirements, and consider developing custom packaging solutions for bulk corporate orders.

Establish clear guidelines for minimum order quantities and customization possibilities, ensuring efficient production while meeting client expectations. Develop sample kits and visualization tools to help corporate clients understand available options and make informed decisions.

Retail Market Considerations

For retail markets, focus on creating attractive packaging that showcases the product's quality and features. Design display-ready packaging that protects the clips while allowing customers to appreciate their transparency and finish. Consider developing themed collections or seasonal color variations to appeal to retail consumers.

Include clear usage instructions and highlight key features such as document capacity and durability. Create size assortment packs that cater to various consumer needs while maximizing retail shelf space efficiency.

Frequently Asked Questions

What makes acrylic PP clips superior to traditional metal clips?

Acrylic PP clips offer several advantages over traditional metal alternatives. They provide better visibility of documents due to their transparency, won't rust or corrode, and are gentler on papers. The combination of acrylic and PP materials also allows for more design flexibility and customization options while maintaining durability.

How long can acrylic PP clips be expected to last?

When properly manufactured and used as intended, acrylic PP clips can maintain their functionality for several years. The high-quality acrylic remains clear and doesn't yellow, while the PP components retain their spring action through thousands of uses. Proper care, such as avoiding extreme temperatures and excessive UV exposure, can further extend their lifespan.

What are the key factors in choosing the right acrylic PP clip size?

Selection should be based on several factors including the number of sheets to be held, the type of documents being secured, and the intended use environment. Standard office documents typically work well with 25mm to 50mm clips, while larger projects may require wider sizes. Consider both the width and gripping strength needed for your specific application.